Test machine lineup

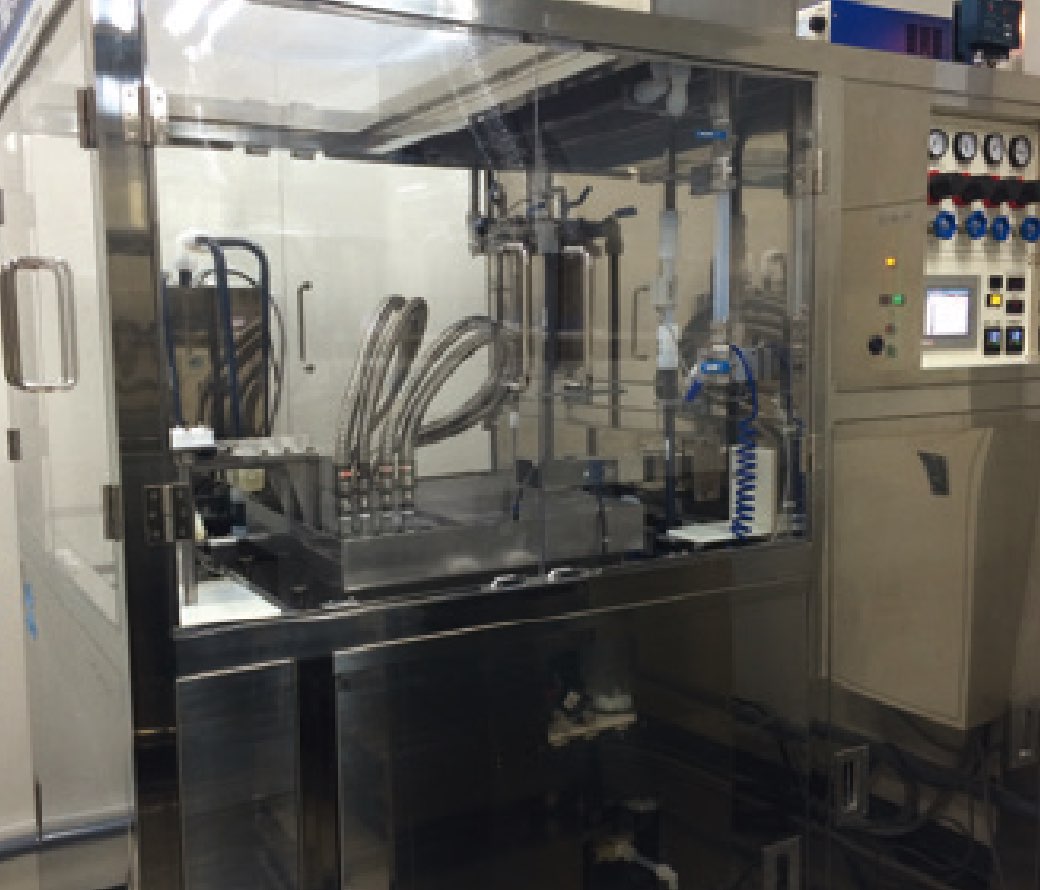

Batch etching equipment

Available substrate sizes : 4 or 6-inch carrier × 2-cassette processing

Conveyance : Automatic conveyance, chuck system

Etching bath : 4-side overflow structure

Temperature adjusting function : Provided, 20°C to 80°C

Shaking mechanism : Provided, up-down (with a wafer rotation function)

QDR bath : With a shower function

Final rinse bath : With a specific resistance meter

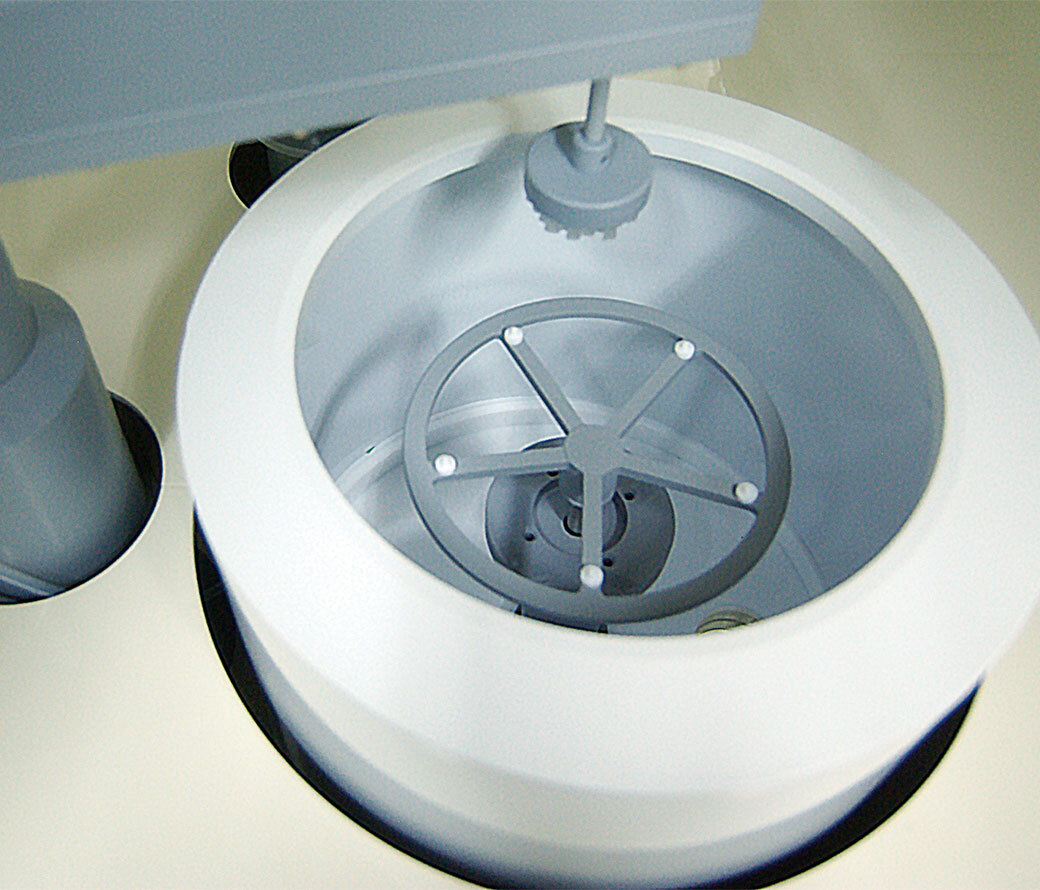

Spin etching equipment

Available substrate sizes : 2, 3, 4, or 6 inches

For square substrates, please contact us.

Temperature adjusting function : Provided, max. 80°C

Chemical nozzle : 2 heads (One is a two-liquid mixing nozzle.)

Rinse nozzle : 1 head (capable of micro/nano bubbling)

Air blow : Provided

Chuck structure : Pin chuck

Chemical supply : Polyethylene tank

Chemical collection : Polyethylene tank

Lift-off equipment (1)

Available substrate sizes : 2 to 12 inches

For square substrates, please contact us.

High-pressure jet nozzle : Twin (vertical and oblique nozzles)

Jet pressure : 3 to 15 MPa (Temperature adjusting jet available, max. 100°C)

Paddle nozzle : Provided

Double-side rinse: Provided

Air blow : Provided

Chuck structure : Pin chuck or suction chuck

With a peeling chemical reuse system

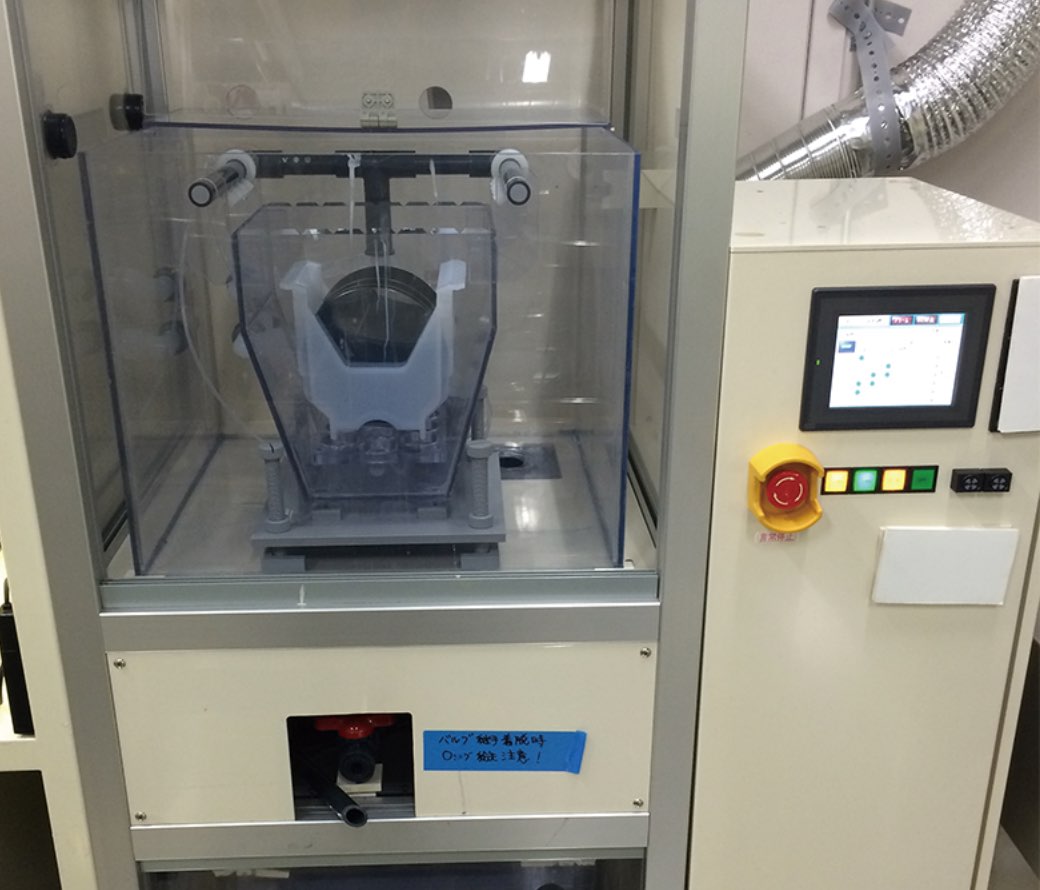

Lift-off equipment (2)

Available substrate sizes : 2 to 8 inches

High-pressure jet nozzle : Twin (vertical and oblique nozzles)

Jet pressure : 3 to 20 MPa (Temperature adjusting jet available, max. 100°C)

Two-fluid nozzle : Provided

Paddle nozzle : Provided

Double-side rinse : Provided

Air blow : Provided

Chuck structure : Pin chuck or suction chuck

With an automatic chamber cleaning function

With a peeling chemical reuse system

With an automatic wafer conveyor robot

Peeling equipment (1), One-side overflow bath

Available substrate sizes : 2 to 12 inches (*8 inches for 15-wafer processing)

For square substrates, please contact us.

Temperature adjusting function : Provided, max. 100°C

Shaking mechanism : Up-down

Bath structure : One-side overflow structure

Chemical volume : About 35 L

Bubbling mechanism : Provided (peeling mode/ejection mode)

Ultrasonic function : Provided (frequency: 40 kHz; output: 600 W)

Filter circulation + ISF function

Suffix circulation function : Provided

Ultrasonic monitor : Provided

Peeling equipment (2), overflow bath with the DoM Jet System

Available substrate sizes : 2 to 8 inches (2 to 4 inches are available for two-cassette processing) For square substrates, please contact us.

Temperature adjusting function : Provided, max 100°C

Shaking mechanism: Up-down/side-to-side

Bath structure: One-side overflow structure

Chemical volume : About 65 L

Ultrasonic function : Provided (frequency: 38 kHz, 80 kHz, 120 kHz, 165 kHz; output: 600 W) Filter circulation + ISF function

Suffix circulation function : Provided

Ultrasonic monitor : Provided

USF (ultra-mesh filter) : Provided

QDR bath

Available substrate sizes : 2 to 6 inches One-cassette processing

Temperature adjusting function : No

Shaking mechanism : No

Bath structure : Four-side overflow structure

With an upper shower nozzle

Bath capacity : About 10 L

Bubbling mechanism : No

Ultrasonic function : No

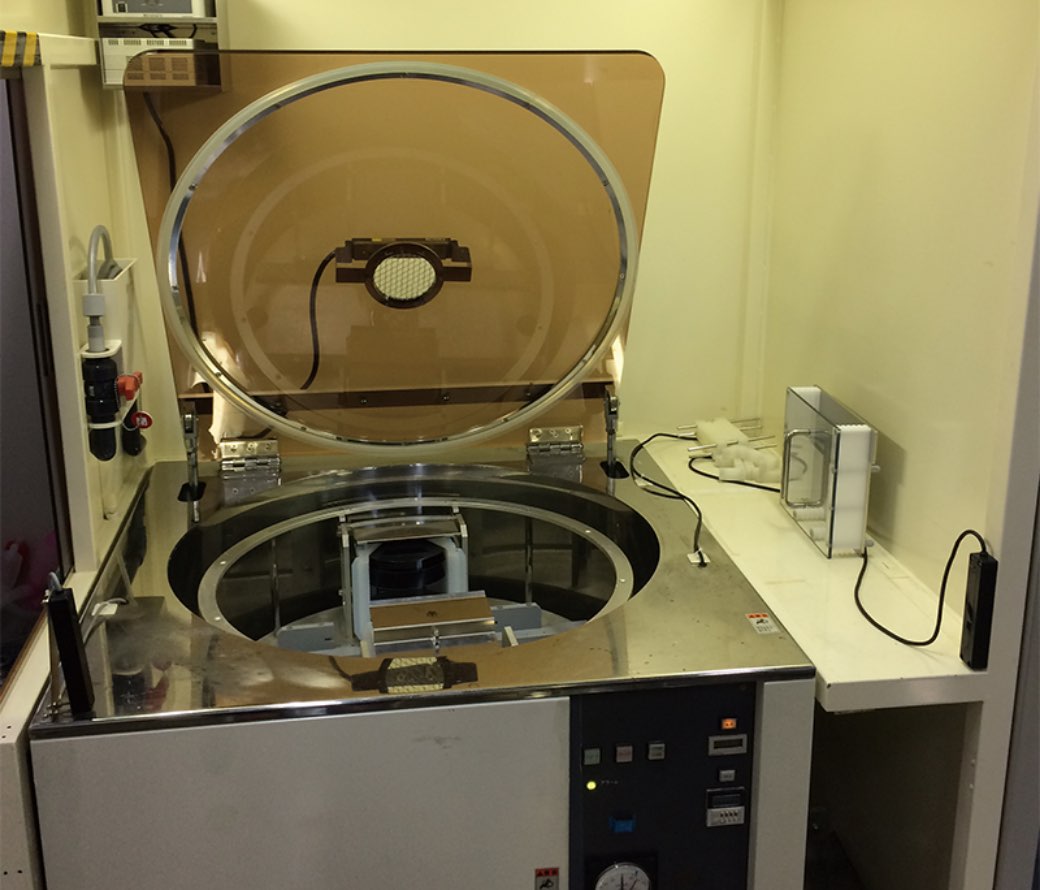

Drying equipment: Spin dryer

Available substrate sizes : 2 to 8 inches

System : Opposing system

Rotating speed : Max. 800 rpm

Ionizer : Provided

HEPA unit : Provided

Tokyo Test Center

Dalton has a variety of testing machines where customers can select their equipment with a peace of mind.

Tokyo Test Center

Dalton Corporation

1-1-9, Narihira, Sumida-ku, Tokyo (on the premises of the Sumida Logix Co., Ltd.)

Zip code: 130-0002

- Honjo-azumabashi Station, Exit A2 (Toei Asakusa Line)

- Tokyo Skytree Station, Exit 1 (Tobu Skytree Line)

- Oshiage Station, Exit B2 (Tokyo Metro Hanzomon Line/Keisei Line)

(Seven to eight-minute walk from any of the stations above.

*20-30 minutes from Tokyo station)