Safety measures

The most important priority in our products is customer safety.

Hazardous chemicals such as organic solvents and acid and alkaline chemicals are used in the equipment.

Dalton is a comprehensive manufacturer of fume hoods and exhaust gas processing equipment,

and utilizes the know-how acquired through research and development in order to provide products that are not only considered stable in performance and operability, but also ensure customer safety.

SAFETY MEASURES SUCH AS SENSORS

Emergency stop button

This button is provided on the main unit of the equipment. If it is pressed, the equipment will be powered down.

Temporary stop button

This button is provided on the main unit of the equipment. If it is pressed, the conveyor and the wafer conveyor robot temporarily stop.

Area sensor

This sensor is provided on the workpiece feeding and discharging sections.

If the sensor is turned on, the shuttle mechanism, the conveyor, and the wafer conveyor robot are temporarily stopped so that they do not make contact with the workers. Products that are safety-standard compliant can be installed, depending on your requirements.

Signal tower

This indicates the operating state of the equipment.

(Example: During an automatic operation, it blinks in blue. When an alarm is given, it blinks in yellow. When a warning is given, it blinks in red.)

Exhaust pressure sensor

A pressure sensor is installed on each duct.

A warning is given if the exhaust pressure drops or a fan stops.

Alarm and warning

Alarm: A minor indication.

Warning: A serious event that causes a problem with the operation of the equipment.

The operation of each device will be determined through discussions.

Door sensor

A sensor is installed on each door.

When a door is opened, the equipment temporarily stops and an alarm is given.

Pressure sensor

This sensor is installed on the primary-side pressure line of the air, N2, and pure water.

It gives a warning when the pressure supplied on the primary side decreases or when the pressure supply stops.

Water leak sensor

This sensor is installed at the bottom of the main unit of the equipment. If a water leak is detected, the entire liquid system stops and a warning is given.

Measures against over-temperature

Install redundant temperature sensors.

If an over-temperature is detected when the temperature adjusting sensor is broken, the heater power supply is shut down.

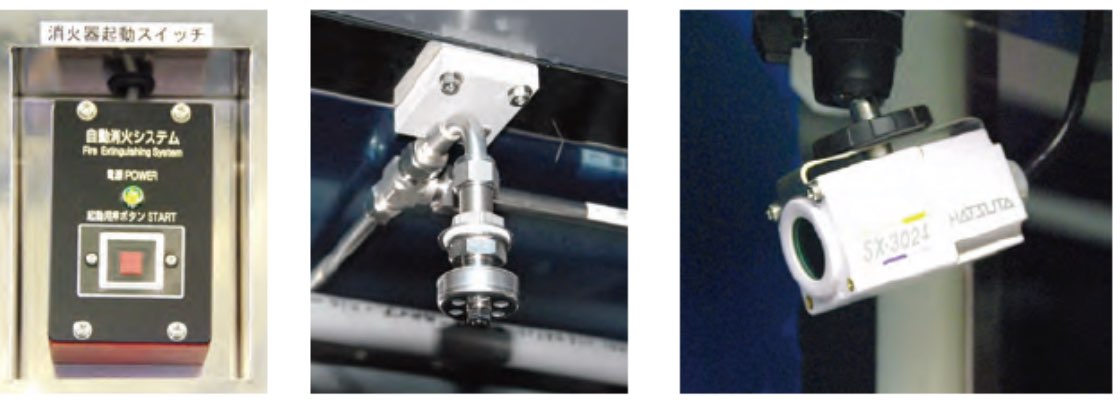

Temperature/infrared ray sensors

This sensor always monitors the internal temperature and the ignition of the equipment. If an abnormality occurs, the automatic extinguishing system is activated.

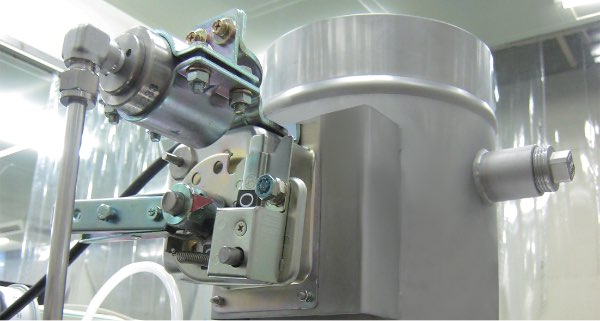

Gas pressure damper

The damper is automatically closed in response to extinguishing gas from the automatic extinguisher.

The damper is closed in order for the inside of the equipment to be filled with extinguishing media (CO2), and also for the prevention of fire from spreading towards the factory exhaust side.

Wire glass or reinforced glass

This prevents glass from being broken into pieces and scattering when a fire or explosion occurs inside the equipment.

Explosion pressure hatch

This is provided on top of the ceiling of the equipment in order to release its internal pressure when a fire or explosion occurs inside the equipment.

The hatch returns to normal when the internal pressure decreases.

Safety measures related to the housing and other specifications

The structure of the floor drain pan of the equipment

Even if large amounts of chemicals are leaking from the chemical bath, the drain pan at the bottom of the equipment can receive the leaking chemicals, preventing chemicals from coming out of the equipment.

Design that considers maintenance

A design that considers the maintenance of pumps, filters, etc., reducing the amount of time for filter replacement, etc.

Separated water discharging line

The pure water and chemical lines are separated. Water is discharged separately in order to prevent reaction heat from causing problems.