PRODUCTS

POWDER MACHINERY

Granulation

Extrusion granulation

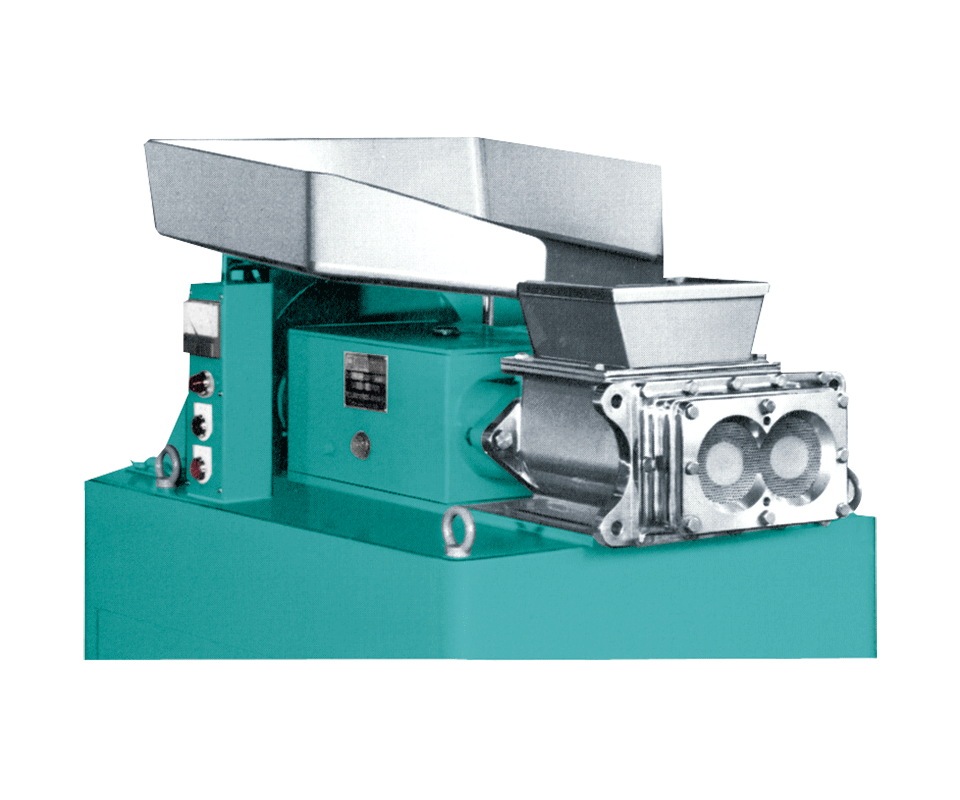

Twin Dome Granulator

By using the unique dome shaped screen (Dome Die), the fine granules with a diameter of 0.3 mm can be produced.

- Applicable to the fine-granule with a pilot scale production and the low-volume high-mix production.

- GMP design

- Dome Die and Screw Case are easily disassembled so that the powder-contacting parts can be cleaned by a water.

- Particle diameter: 0.3 mm to 2 mm in diameter

- Product shape: Cylindrical

Application examples

- Pharmaceutical products

- Seasonings

- Granulated sugar

- Health food products

- Agrochemical products

- Fish Feed

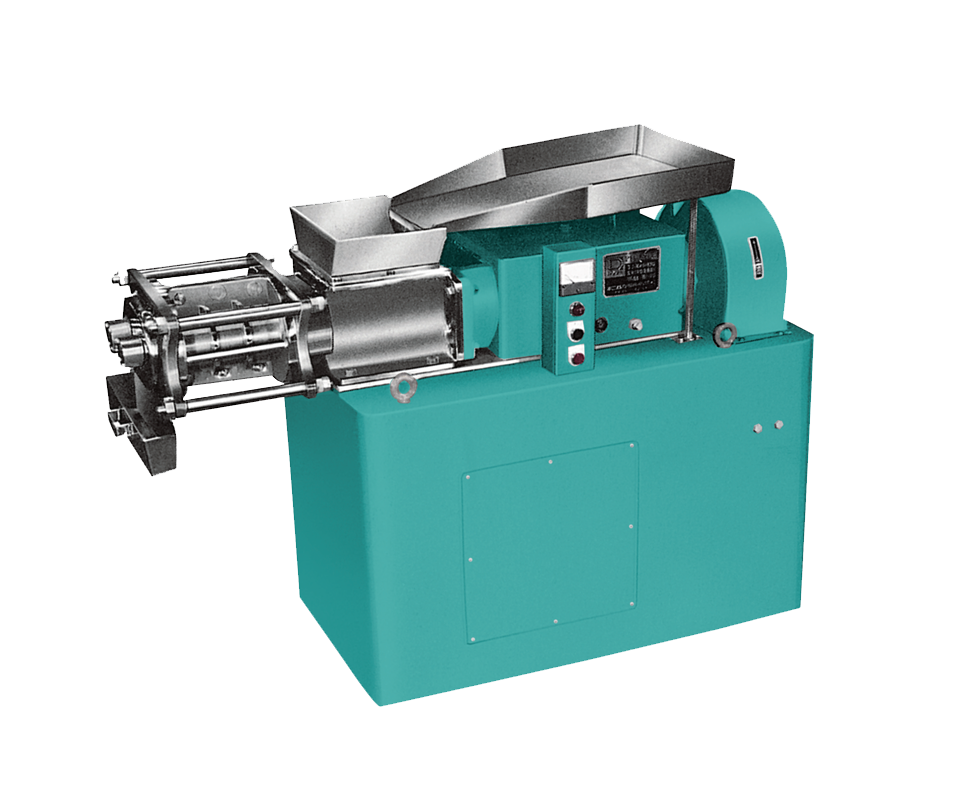

Extruder Twin Screw type EXD (Radial Extrusion)

- The pioneer of wet extrusion granulator in the world.

- All powder-contact parts to the product can be easily disassembled and re-assembled.

- Available in Heating/ Cooling Jacket

- GMP design is available

- Particle diameter: 0.5 mm to 3.0 mm in diameter

- Product shape: Cylindrical

Application examples

- Pharmaceutical products

- Seasonings

- Health food products

- Agrochemical products

- Fish Feed

Extruder Twin Screw type EXDF (Frontal Extrusion)

- Wet extrusion for larger particle diameter

- Higher compression at extrusion compare to EXD type

- Capable of using as Radial extruder EXD by exchanging the extrusion attachment

- Particle diameter: 1.5mm to 10.0mm in diameter

- Product shape: Cylindrical

Application examples

- Sewage Sludge

- Clay

Fine Granulator EXR

- Extrusion by the overlapped Double extract (blade)

- Lower compression at extrusion compare to EXD type

- Capable of using as EXD by exchanging the extrusion attachment

- Particle diameter: 0.5 mm to 3.0 mm in diameter

- Product shape: Cylindrical

Application examples

- Pharmaceutical products

- Seasonings

- Health food products

- Agrochemical products

- Fish Feed

Basket Extruders BR-200, 450 and 600

This is a conventional basket type wet extruder, which is capable to process variety of applications from the pilot scale to the production level.

- Uniform extrusion, no overflow across entire screen area, which lead to high product yield.

- Not only for extrusion, but also some kneading effect generated at the chamber, so relatively less mixing and kneading time required on the upstream process.

- Easy Scale-up and process repeatability can be made among the different scale of the machines of the 200, 450, and 600.

- Choice of extrusion blades available to suit process.

- Variable shaft speed either variable frequency drive or mechanical speed drive available to meet product properties.

- Rotating product discharge table.

- Easy disassembly for cleaning at extrusion zone : The screen and its holder consist of a two-section system. All other contact parts to the products can be easily disassembled, cleaned and re-assembled.

- General range of extrudate diameters : 0.5 mm to 3.0 mm in diameter and cylindrical shape.

Application examples

- Crop Protection products

- Chemical Products

- Food Products

Basket Extruders BR-300G

This is a basket type wet extruder, corresponding to concept to GMP design.

- Easy disassembly for cleaning at extrusion zone : Almost of the component parts can be easily disassembled and re-assembled without tools.

- Air purging shaft seal available at the time of cleaning

- Uniform extrusion, no overflow across entire screen area, which lead to high product yield.

- Not only for extrusion, but also some kneading effect generated at the chamber, so relatively less mixing and kneading time required on the upstream process.

- Variable shaft speed via variable frequency drive.

- Rotating product discharge table, and adjustment location of discharge chute can be made.

- General range of extrudate diameters : 0.5 mm to 3.0 mm in diameter and cylindrical shape.

Application examples

- Pharmaceutical products

- Food Products

Basket Extruders BR-300F

This is a basket type wet extruder, focusing on to meet food application process.

- Cabinet type, direct drive compact design

- Easy disassembly for cleaning at extrusion zone : Almost of the component parts can be easily disassembled and re-assembled.

- Air purging shaft seal available at the time of cleaning

- Uniform extrusion, no overflow across entire screen area, which lead to high product yield.

- Not only for extrusion, but also some kneading effect generated at the chamber, so relatively less mixing and kneading time required on the upstream process.

- Variable shaft speed via variable frequency drive.

- Rotating product discharge table.

- Choice of extrusion blades specialized food applications available to suit process.

- General range of extrudate diameters : 0.5 mm to 3.0 mm in diameter and cylindrical shape.

Application examples

- Food Products, such as seasoning, condiment, flavors, solid soup and additives etc

Spheronization

Spheronizer/ Marumerizer

- Converting the cylindrical shaped granule into the spherical shaped granule by the friction force, the driving force and the centrifugal force.

- Also different length of cylindrical granules are converted into uniform length in a short operation time

- Spherical granules can be produced with narrow/sharp particle size distribution with high yield

- All powder-contact parts to the product can be easily disassembled and re-assembled.

- GMP design is available

- Particle diameter: 0.4 mm to 10 mm in diameter

- Product shape: Spherical granule

Application examples

- Pharmaceutical products (Coating for the Drug Delivery System of pharmacy)

- Agrochemical products (Coating for the sustained release of WDG)

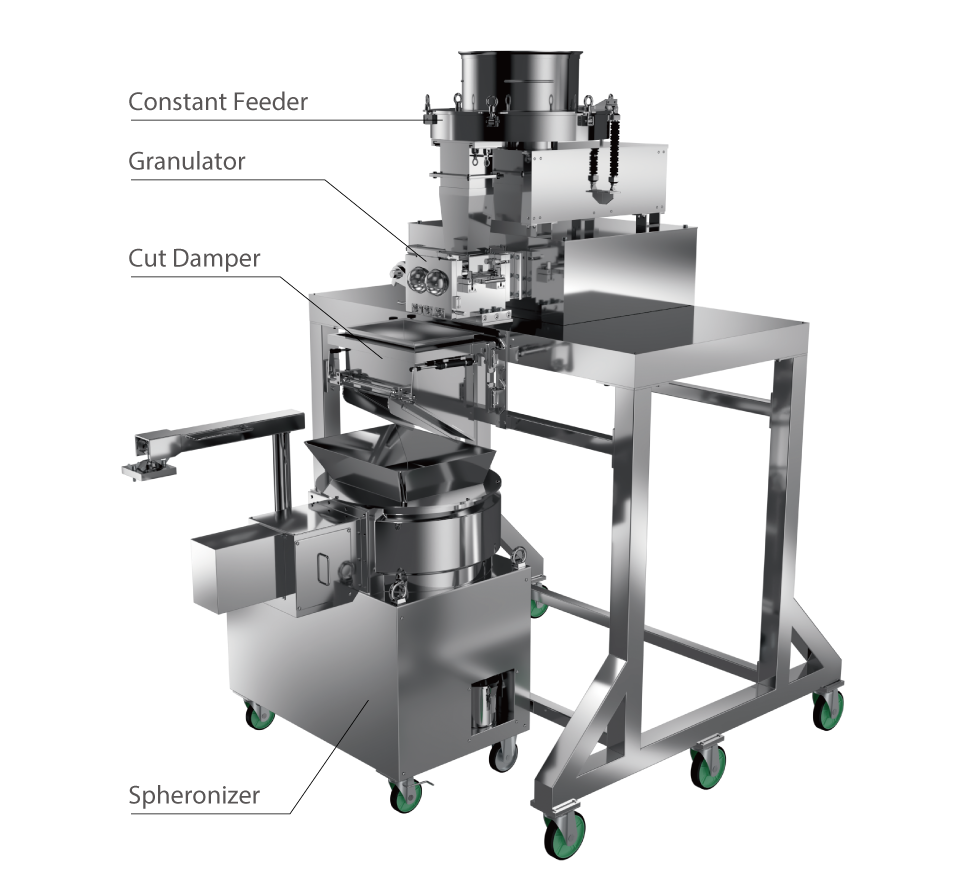

Granulation and extrusion granulation

Combined Granulation System

Multiple devices are combined from the product feeding to spheronization.

By reducing the human intervention in the process, it contributes to the stable product quarity and the labour cost reduction.

- Each device is redesigned so that its structure is suitable for integration.

- Granulator can be chosen to meet the desired capacity, granule size and so on.

*For more details, see the specifications of each device.

Granulating and spheronizing equipment

Spartan Granulator

One-step process for dry mixing and wet granulation by adding the liquid

Single rotor and mixing blade are provided in the chamber horizontally. After dry mixing, the liquid shall be added to form wet mass which is then disintegrated into fine granules by the pins on the rotor rotating at high speed.

Spartan Granulator Multi-chopper type

Latest model for better mixing and granulation

This equipment has multi-chopper to increase the efficiency of mixing and granulation. By increasing the number of the choppers, the product yield can be simulated to small/labo.

Agitation and granulation

SP Granulator

This single unit performs processes from kneading and agitation and granulation.

The single unit performs processes from kneading and agitation and granulation, taking roles for two machines and thereby improving productivity. Replacing the blades allows the machine to perform kneading, thus it is suitable for preprocessing for extrusion granulation.

Continuous granulation

DOME-EX continuous granulation system

To the continuous granulation processing from the batch operation.

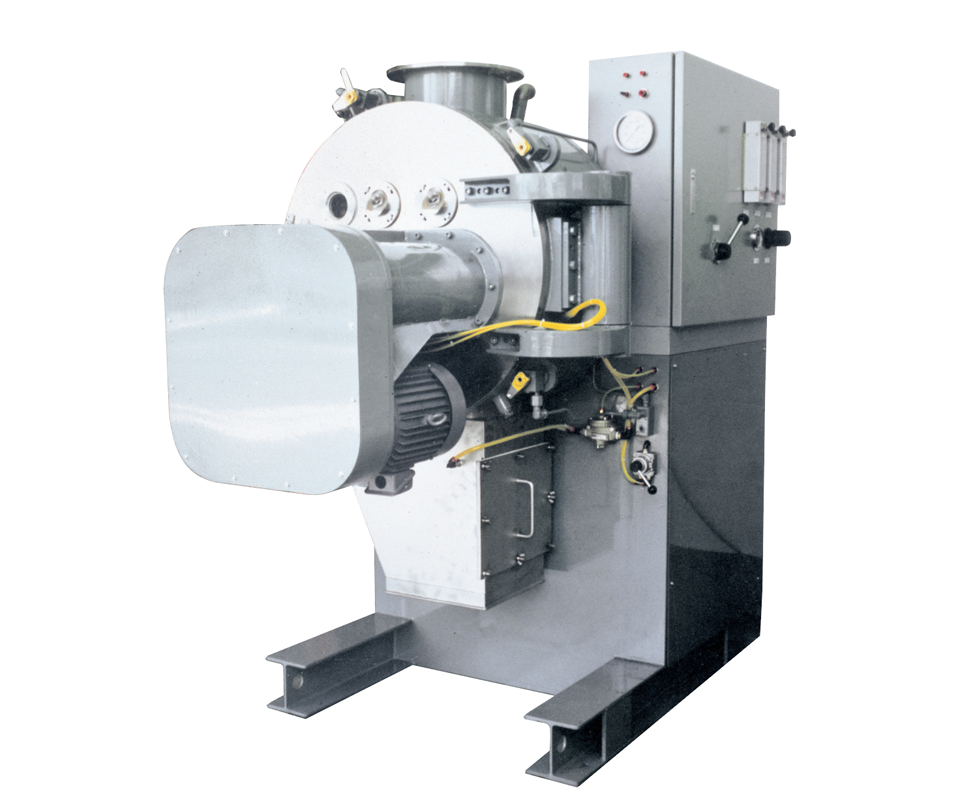

Pressure swing granulation

Swing Processor

A new system that takes advantage of the adhesive and coherent property of powder.

By thinking from a totally different angle and taking advantage of the adhesive and coherent property of fine powder itself, we succeeded in designing and developing a completely new system that granulates without binder. This is a new type of a granulator system that will surely change the current state and future of granulation.