PRODUCTS

POWDER MACHINERY

Mixing

Dry and wet mixing

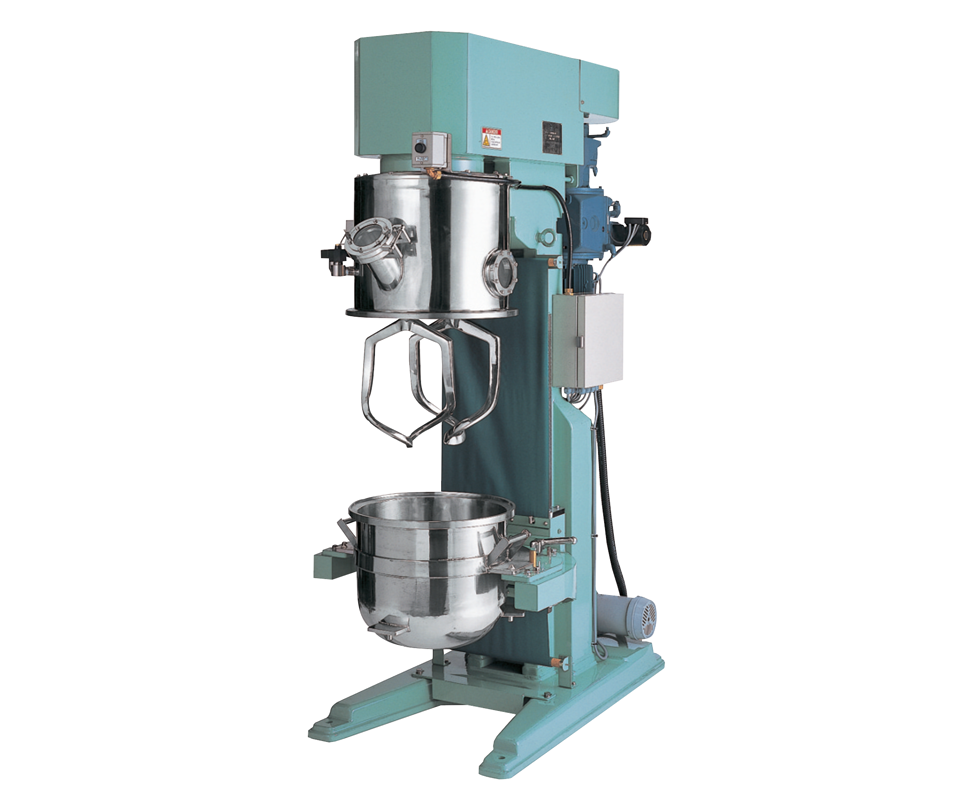

5NDM/5XDM/5DM Planetary Mixer

Compact type for laboratory purpose

Speed change can be controlled during the operation by changing the clutch of 2-step speed reducer and 4-step belt-changeover system.

There is a wide range of equipment suitable laboratory purposes from basic type to the contamination prevention type as well as vacuum type.

25NAM/25XAM/25AM Planetary Mixer

This series of machines features high-performance mixers equipped with a non-step speed changer that is ideal for production testing.

These mixing machines are equipped with a non-step speed changer ideal for production testing.

DM/DMV Planetary Mixer (with a gear speed changer)

These high-operability basic models offer quick, high-precision mixing

These machines can offer all kinds of raw material agitation and mixing, from the mixing of powders to the kneading of high-viscosity substances.

XDM/XDMV Planetary Mixer

Capable to select proper rotation speed based on the materials via non-step speed change system

Proper rotation speed can be selected depending on the material through non-step speed change system.

Spartan Mixer

This is a high performance, high shear mixer for the dry mixing.

- Unique Structure : A high-speed chopper rotor horizontally center-mounted and a mixing arm to eliminate the dead zone in the mixing chamber, which can contribute to make product dispersion uniformly and efficiently in very short period of time.

- A high speed – large chopper produces strong shearing force and makes effective dispersion even against sticky and agglomerate natured products.

- High cost performance due to the very short dispersion-mixing time taken, which could consider a relatively smaller scale machine to process the same volume than on different type of mixers, and this could lead to less installation spaces, energy taken and other equipment scales involved in the process line.

- Easy disassembly for cleaning

- High product yield, less product left in the mixing chamber at the time of discharge

- S-cutter type of knives instead of the chopper rotor as an option can be available against adhesive products.

- As additional process function in the Spartan mixer, surface modification on process products can be obtained depending on the process products

Application examples

- Pharmaceutical products

- Electrical Materials

- Materials for Battery

- Chemicals

Wet mixing

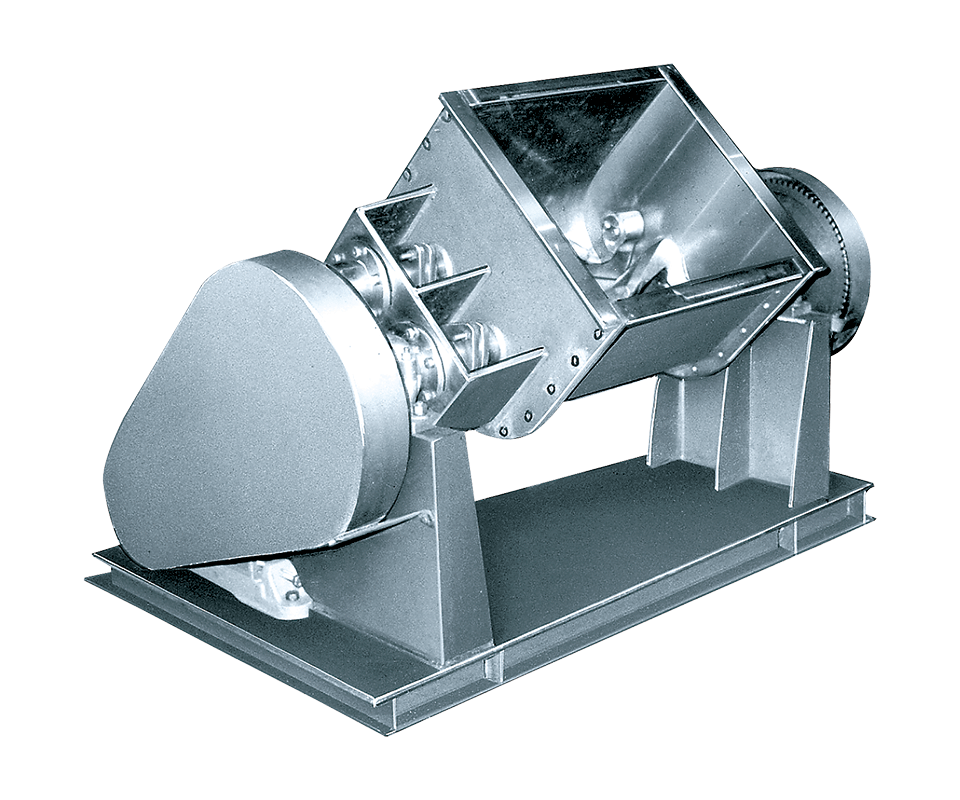

Kneader

With this machine, materials of a range of viscosities from low to high can be evenly mixed and kneaded.

The mixture is repeatedly compressed, pulled, and sheared via the strong rotation of the special agitating blades lined up in parallel inside the fixed container, such that the mixture is completely kneaded in a short time.

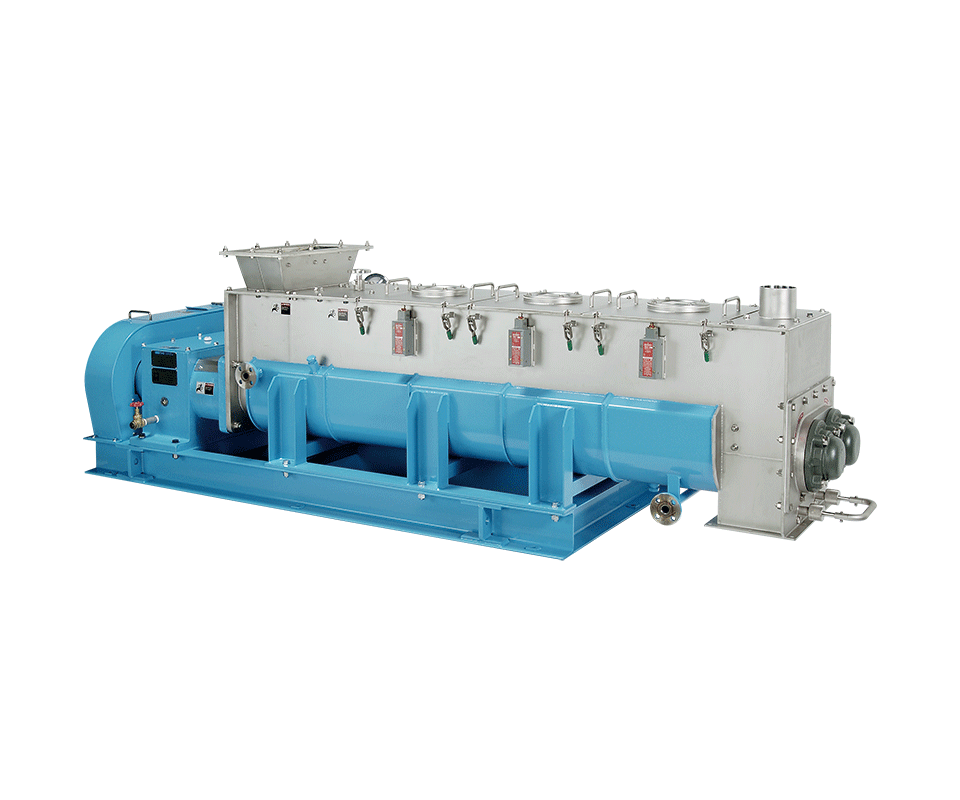

Continuous Kneader

This machine offers high performance in continuous powder kneading or granulation preprocessing.

The raw material is mixed and wetted (a separate moistening system is required) via the rotation of the special blades lined up on the parallel shafts inside the fixed twin-hemicycle container.

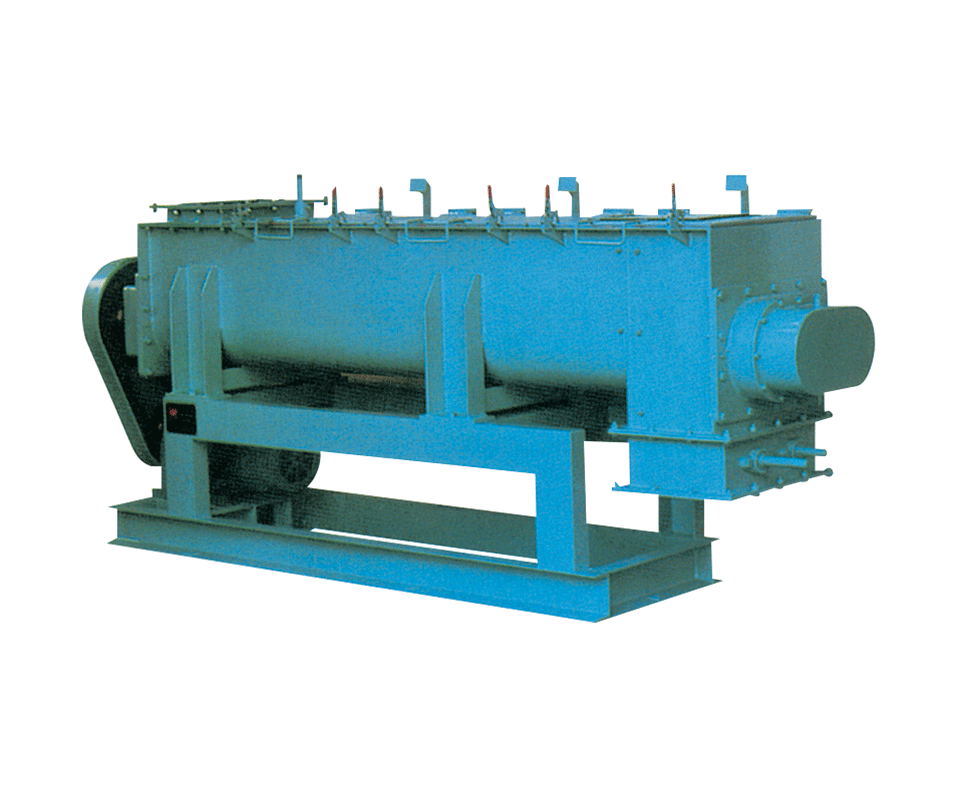

Pug Mixer (a continuous mixing machine)

This multifunction mixing machine is superior in the continuous mixing, agitation, and moistening of powder.

The machine features special blades on the two shafts lined up in the fixed twin-U-shape container, and the blades each rotate in the outward direction at a constant speed so as to cause the supplied raw material to move toward the center so that it is continuously mixed.